Heat pumps

Part 1

A heat pump is an Air Conditioning system which can also provide very efficient heating. It takes less energy to relocate heat than it does to create it. Just as a refrigeration system removes and relocates heat from a cooler or freezer, so too does a heat pump remove heat from cold outdoor air and relocate it to within a building. A 4 way reversing valve is used to swap the functions of the evaporator and condenser in order to change from cooling to heating mode. To avoid confusion it is common practice to call heat pump coils the "indoor" and "outdoor" coil. The diagram below shows a heat pump piping layout. Click back and forth between Buttons 2 and 3 and note how the discharge from the compressor is diverted to different coils in each mode. You can also view the 2 modes showing the refrigerant states with Buttons 4 and 5.

Piping Layout

4 Way Reversing Valve

Here is another view of how the 4 Way Reversing Valve  diverts flow; the pipe on the single stub side of the valve is always the discharge from the compressor. The discharge is diverted to the condenser, the middle stub is always suction going to the compressor, and the left over stub is always from the evaporator. The switching function is accomplished by the sliding back and forth of an internal barrel which has diverting passages. The systems own high side pressure is used to ram the barrel to the desired end by a pilot duty solenoid valve. On the diagram below, click back and forth between Buttons 3 and 4 to see the barrel slide to opposite ends. Then try Buttons 5 and 6 to see the refrigerant flow being diverted.

diverts flow; the pipe on the single stub side of the valve is always the discharge from the compressor. The discharge is diverted to the condenser, the middle stub is always suction going to the compressor, and the left over stub is always from the evaporator. The switching function is accomplished by the sliding back and forth of an internal barrel which has diverting passages. The systems own high side pressure is used to ram the barrel to the desired end by a pilot duty solenoid valve. On the diagram below, click back and forth between Buttons 3 and 4 to see the barrel slide to opposite ends. Then try Buttons 5 and 6 to see the refrigerant flow being diverted.

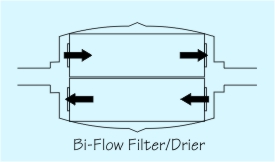

Liquid Line Check Valves & Bi-Flo Driers

The Liquid line always carries liquid but the direction of flow reverses in each mode. Each coil has it's own metering device with a check valve piped in parallel. When refrigerant flow meets a check valve in the blocked direction it has no choice but to divert through the TXV. When refrigerant flow meets a check valve in the allowed direction it will take the route of least resistance and go through the check valve and ignore the TXV. There are TXVs that have this check valve function built right into the valve itself. The Bi-Flow filter/drier  works in a similar manner. Inside a bi-flo drier there are check valves which ensure that refrigerant flow goes through the drier core in the same direction regardless of the liquid line flow direction. The drier core must experience flow in one direction only. Otherwise, if counter-flow was allowed debris that had been filtered out would unload and re-enter the system.

works in a similar manner. Inside a bi-flo drier there are check valves which ensure that refrigerant flow goes through the drier core in the same direction regardless of the liquid line flow direction. The drier core must experience flow in one direction only. Otherwise, if counter-flow was allowed debris that had been filtered out would unload and re-enter the system.

Accumulator

Defrost

The outdoor coil of a heat pump can frost up just like a freezer evaporator. The tendency to frost up increases with humidity and low ambient temperatures. There is fortunately a convenient method of defrosting the outdoor coil and that is to make the system run in the cooling mode. The outdoor coil becomes the condenser and the frost can be melted away. To keep the heat where it is wanted the outdoor fan motor is temporarily shut off. All this happens automatically and is controlled by a solid state defrost control board. Every so often it will check the temperatures of some thermistors (temperature sensitive resistors) and if a defrost is needed it will activate the defrost mode. Otherwise it will wait for the next trial for defrost. As the defrost continues, steam will rise out of the unit. New heat pump owners should be advised to expect this. Otherwise nuisance calls may be placed by the unknowing customer. They have even been known to call the fire department thinking the unit is on fire. When the defrost is completed, the whoosh of the reversing valve can be heard, the outdoor fan restarts and a final cloud of steam is blown out by the outdoor fan.

In the piping diagram above, place the unit in the defrost mode (Button 2). Note that the outdoor coil has hot gas entering it which is going to condense into a liquid as it melts the ice build up. There is no danger to the compressor because this liquid must travel through a TXV and evaporator before getting back to the compressor. However simulate the end of a defrost by putting the system back into heating mode. (Button 3). Note that the compressor is now directly sucking the contents from the outdoor coil (liquid) without the benefit of any TXV or evaporator to protect it. You have just seen the need for the accumulator in heat pump systems with reciprocating compresors. There is a trend to use scroll compressors in heat pumps. The manufacturers are omitting accumulators in those units because of the scrolls ability to tolerate some liquid content in the returning suction vapours.

The defrost system should get rid of all of the ice everytime it defrosts. If a predetermined amount of time expires the defrost will be terminated irregardless but there should be so little ice left that a successful and complete defrost should be easy to achieve on the subsequent defrost. Normally a complete defrost is accomplished every time. If there is a system or defrost fault ice may continue to grow out of control.