Relays

Relays |

|

|

A relay is a switching device that activates if it's coil receives an electrical signal. Relays can have one or many sets of contacts. It is possible to perform multiple switching functions simultaneously. They come in many shapes, sizes and capacities but they all work in a similar fashion. They have a coil which when energized, causes a strong magnetic force to snap shut an assembly containing sets of electrical contacts. Those sets of contacts can be Normally Open (NO) or Normally Closed (NC) so different circuits can be turned on or turned off at the same time. |

|

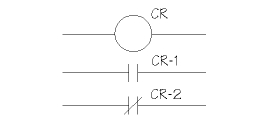

A relay is represented in a schematic diagram as shown in this sketch. The relay is usually given a short name which is placed beside the coil. In this case the CR stands for Control Relay. It's contacts can be named as well and they are given the same name with sequential numbers also added. The top contact, CR-1, is a normally open contact. By "normal" we mean when there is no power to the coil. The lower contact, CR-2, is normally closed. So when there is no power to the coil CR-2 contacts have continuity. The strike through the contacts pictorially represents the fact that the contacts are closed and will allow electrical flow. There can be several contacts and they can be scattered all over a schematic diagram. That's why they must be named, so that the intended operating sequence can be determined. When the coil is energized, all of it's contacts reverse position. The open contacts close and the closed contacts open. Press the On Button to see this demonstrated. |

Time Delay Relays |

|

|

A time delay relay is a switching device whose contacts make or break after a time delay. Some timed relays initiate a delay when the coil signal makes, other timed relays initiate a delay when the coil signal breaks. The latter are used as an "anti-short-cycling device." For example, when a system finishes a call, the timer starts the delay and will not allow a signal through it's contacts until after the delay period. So should a child for example try flicking a mercury bulb thermostat on and off over and over again the equipment will not try starting to all those signals. It will only try starting after the time delay. The timer and switching is done by solid state circuitry so these types of devices are typically pilot duty. In other words they are used in control circuits and send signals to load rated relays and contactors to do the actual switching of loads. Time delay relays are available in many different configurations and are used for lots of diversified purposes in HVAC/R control circuitry. |

|

Time Delay relays usually indicate their contacts on schematic diagrams with the letters TD for time delay or TR for timed relay. Click the on button at the left to see the contact close. Don't forget to wait for it... |

The Non-Recycling Pump Down System |

| When a system is pumped down sometimes a little liquid refrigerant is left over in a long liquid line or in the evaporator. This liquid will evaporate and can build up the pressure to the cut in point on the LPC. The compressor will restart and run for a few moments and pump down some more. Sometimes this can happen several times in a row. If the compressor valves are a little worn and don't hold back properly, discharge pressure can leak back and cause a pumped down system to short cycle indefinitely through what is supposed to be an off cycle. It is not good to short cycle a compressor or for that matter any electrical motor. Valve wear can of course be severe enough to warrant compressor repair or replacement but short of that there is a way to address both of these situations with a control system. The Non-Recycling Pump Down control system makes use of a couple of relays. |

|

Diagram |

|

Off Cycle: evap fan only |

|

T-Stat On: call for cooling, NRR coil energised

(Non-Recycling Relay), LLSV opens, pressure starts to rise |

| LPC On: power flows through NRR contacts

and energizes HOLD coil...continued... |

| Compressor and CFM also brought on |

|

T-Stat Off: starts pumping down. circuit maintained through

HOLD contacts even though NRR dropped out |

| LPC Off: system pumped down and awaiting

call |

|

LPC On (False Call from bleed back) held off by NRR

contacts |

|

You may not come across a non-recycling pump down system very frequently but this circuitry is still a "must know".

This control circuitry introduced the:

Holding Circuit (The HOLD relay)

It demonstrated how a relay can be held in by it's own contacts. It also demonstrated how complex functionality can be accomplished with a small number of controls. |