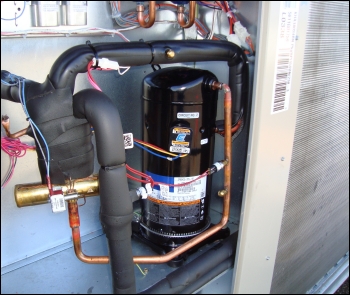

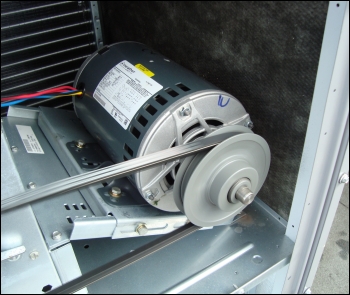

An HVAC system is designed to combust fuels or consume electrical energy to provide heating or cooling to a conditioned space. These systems must be controlled and made safe. Operating controls sense temperature and signal the system to operate or shut off and rest. Safety controls sense operating parameters and shut down the system if undesirable or unsafe conditions occur. The starting point for troubleshooting any system should be knowledge of what the system is and what it is supposed to do. One needs to know whether a particular component should be operating or energized or not operating or not energized. A window air conditioner has two moving parts; a compressor and a double shafted fan motor. When the control system calls, these two components need to operate. A two stage heat pump with two compressors, four outdoor fan motors, an indoor blower motor and two reversing valves is a different story. That system has a variety of operational modes; 2 stages of cooling, 2 stages of heat, a defrost mode, and a fan only mode. Specific combinations of components need to be energized and operating to facilitate the different modes of operation. Before beginning to troubleshoot it, one must know what components are supposed to be operating in each mode. It helps to know that a heat pump loses capacity as the ambient temperature drops. So heat is needed the most when it is the least available from the heat pumps. For this reason control systems are designed to combine both compressor stages as the first heating stage. Knowing this, if this system is operating in the heating mode and one of the two compressors is inoperative it should be obvious that there is a problem.

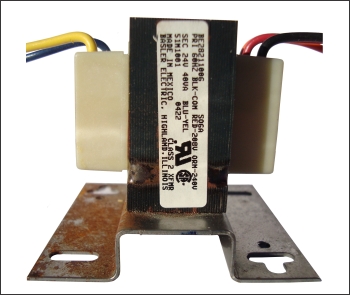

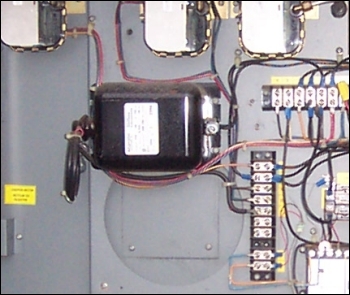

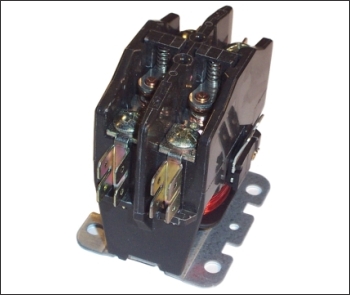

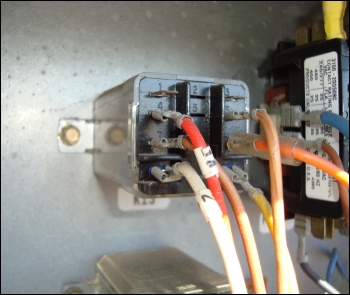

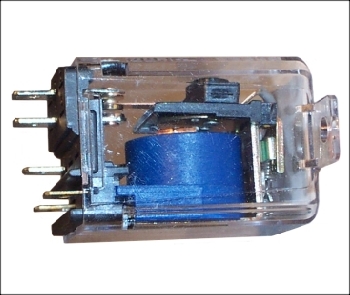

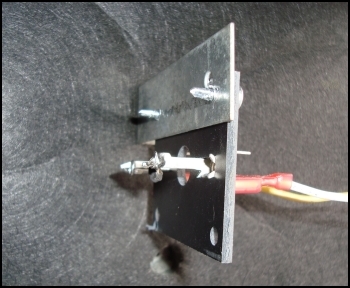

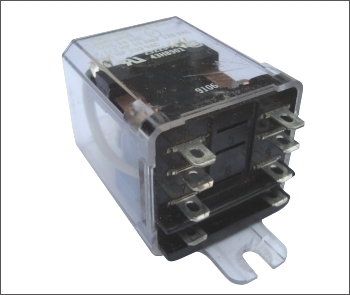

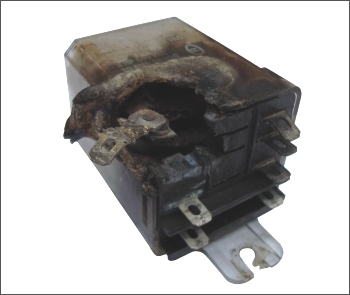

A condenser fan motor should always be operating any time the compressor is operating. Or should it? If the system is equipped with a fan cycling control for low ambient operation then it's proper for the fan motor to cycle off and on during cold ambient conditions to maintain refrigerant head pressure. If the system is a heat pump then it is proper for the outdoor fan motor to be off during the defrost mode. System knowledge is very helpful when troubleshooting. Observation and attention to detail can also be very helpful when troubleshooting. The adjacent relay has had a catastrophic failure. While installed in the unit it may be difficult to notice. It may be obscured by wiring and other components but by being observant and noticing it visually just think for a moment how much electrical troubleshooting could be avoided by zeroing in on the problem area right away.

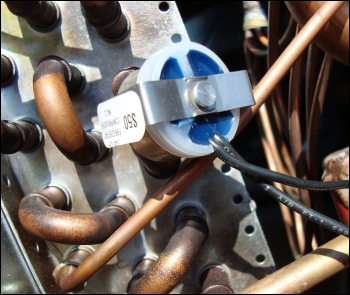

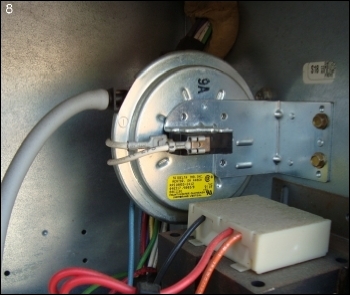

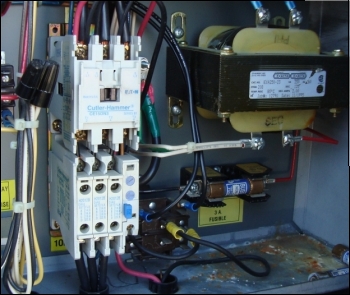

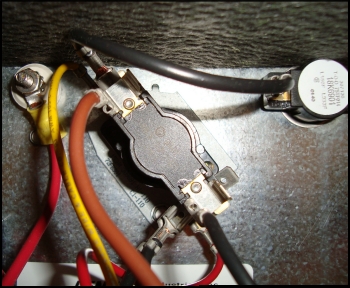

If a V-Belt is chirping or squealing because it is worn or loose that's a signal that the airflow may be inadequate and coils may be frosting up, heat exchangers may be overheating and safety controls may be open. Paying attention to detail, even audibly, can help with troubleshooting. Dirty coils and blower wheels can affect airflow and cause safety controls to open. Burnt contacts, charred wiring, carbon spark residue and charred coil enclosures are more examples of things that can be noticed visually. It is a wise troubleshooting procedure to use your eyes and ears rather than assume that test instruments are the only route to a diagnosis. Think about what a system should be doing versus what it is actually doing. If a heat pump is iced up, why not look to see whether the 4 way reversing valve wiring plug has popped off of the valve coil or if the defrost sensor is properly attached to the appropriate end bend on the coil before even thinking about bringing out any test instruments.